Italian Plastic Machinery: State of the Industry Report 2013

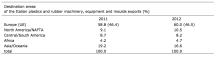

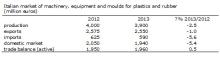

Recovery in exports, which gained momentum particularly in the last quarter of 2013, with a last minute surge in December, allowed the Italian manufacturers to compensate for the lasting weakness in the domestic market which can be seen in Exhibit 1. The very slight decline in demand from abroad, which represents over 65% of total production, kept revenue losses within 2.5% with respect to 2012 and further improved an already very positive balance of trade. In terms of revenues and exports in 2013, Assocomaplast member companies performed better than the average for the sector, with a positive