Italian Print/Convert Machinery: State of the Industry Report 2013

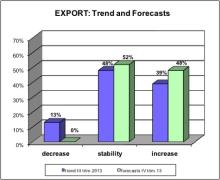

The performance of the Italian industry of printing and converting machinery shows overall stability. This was revealed by the quarterly qualitative survey carried out by ACIMGA, the Confindustria association of companies operating in the industry. The analysis registered members’ sentiment in the third quarter of 2013 and outlines forecasts for the year’s end. On the domestic revenues front 50% of companies sampled for the survey stated that the quarter under analysis closed off with a generally stable performance, in line with the expectations produced by the previous quarterly study. The