Glass Technology Mexico is the professional exhibition of… More

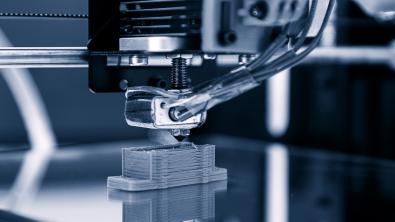

Additive manufacturing will accelerate innovation in industry

Omar Lopez, general director of theMexican Association of Additive Manufacturing and 3D (AMMA3D), commented that "One of the great benefits of additive manufacturing is that it allows companies to give quick answers, because in the design cycle from conceptualization, design and validation of prototypes or final products the time is reduced from months to days."

"In Mexico this has been a boom in the last 10 years. Instead of focusing on the design of the final product, here the product is manufactured, but around another product, such as a turbine. This is where additive manufacturing comes in, creating new opportunities in these industries that are adapting them," he said.

Among the most demanding sectors are automotive and aerospace companies that manufacture parts, for example, GE Aviation began the additive manufacturing journey with one part: the LEAP fuel nozzle. A team of engineers set out to dramatically improve engine efficiency and the fuel nozzle played a significant role in the process, so much so that today the LEAP fuel nozzle powers aircraft that carry millions of passengers around the world. In addition, GE Aviation has since leveraged additive manufacturing in the development of engines, such as the GE9X that contain nearly 300 parts made by additive manufacturing.

In the case of the materials used in additive manufacturing, added Sebastián Romo, managing partner of Skala Ventures, these already resist temperature, friction, mechanics, i.e., it is as if a part were injected in any traditional plastic or resin.

This leads to several benefits, including flexibility, as it allows for a versatile manufacturing scheme and the development of customized products, as is the case in the healthcare sector, which uses additive manufacturing to make prostheses and specific treatments for patients, said Romo.

Lopez added that this benefit also creates new opportunities and also new business models that companies can explore with the adoption of technology.Another benefit is cost savings, listed Romo, given that for the production of 200 or even 10,000 pieces it is more economical through this method, unlike resorting to molds that involve a whole more complex process for its production.In addition, said Lopez, there is the ease of manufacturing complex geometries, optimization of structures (from mechanical, thermal or flow for some applications of heat exchangers, among others that are used in the industry), savings, less waste, which generates a greener life cycle and generates a lower amount of carbon emissions, and the design process is accelerated.For example, in the case of the aerospace industry, the use of additive manufacturing has resulted in lower weight, which generates greater fuel savings. Or, for those companies that are seeking to be socially responsible, by adopting this type of technology within their production lines,

The industry does not have an accurate picture of how it will benefit from the technology, so AMMA3D seeks to break these taboos so that it begins to adopt it in a more efficient way.

Source: Mexico Industry

Recent News

POSTED ON